Did you know that a single bearing can cut energy use by up to 30% in industrial machines? SKF, a leading skf bearing manufacturer, is driving this change with eco-friendly solutions for 2025. As industries demand sustainability, SKF bearings are setting new standards in efficiency and environmental care. This blog explores how SKF’s innovative designs, like the SKF Explorer and Energy Efficient (E2) bearings, are shaping a greener future. From reducing friction to extending equipment life, SKF is revolutionizing the bearing industry. Read on to discover their sustainable strategies and trusted skf distributors like Bearing World.

Green Spin: How SKF’s Sustainable Bearings Are Revolutionizing 2025

Energy Efficiency Through Advanced Design

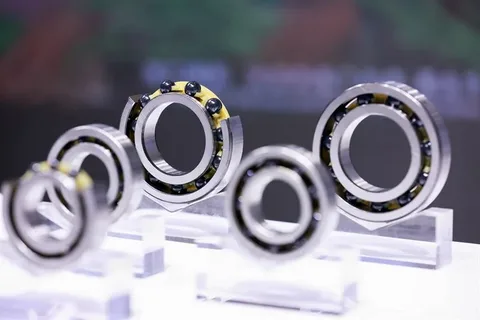

SKF bearings are engineered to reduce energy consumption significantly. Their innovative designs prioritize low friction and high performance.

- Optimized Geometry: SKF Explorer bearings use precise internal structures to minimize friction and heat.

- Energy Savings: SKF E2 bearings cut energy use by up to 30% in light-load applications.

- Real-World Impact: A factory using SKF E2 bearings saved 4,500 kWh per motor annually.

- Long-Term Gains: Lower energy use reduces operational costs and carbon footprints.

Eco-Friendly Materials and Manufacturing

SKF integrates sustainable materials and processes to create environmentally responsible bearings.

- Recyclable Materials: SKF uses high-quality, recyclable steel to reduce waste.

- Advanced Coatings: Special coatings enhance bearing durability, minimizing replacements.

- Green Production: SKF’s factories adopt energy-efficient manufacturing methods.

- Reduced Waste: Optimized processes lower material waste during production.

Extended Bearing Life for Sustainability

Longer-lasting bearings mean fewer replacements, supporting eco-conscious operations.

- Durability Focus: SKF Explorer bearings withstand heavy loads, extending service life.

- Less Maintenance: Robust designs reduce downtime and maintenance costs.

- Remanufacturing Options: SKF’s remanufacturing services restore bearings, cutting waste.

- Circular Economy: SKF Infinium bearings use Laser Metal Deposition for reuse.

Industry-Specific Solutions

SKF tailors bearings to meet diverse industry needs, ensuring sustainable performance.

- Wind Energy: SKF’s bearings in wind turbines boost power yield by 770 million kWh yearly.

- Automotive Sector: Low-friction bearings enhance electric vehicle efficiency.

- Industrial Applications: Bearings support high-speed, high-load machinery.

- Custom Designs: SKF offers solutions for aerospace, mining, and more.

Partnerships with SKF Distributors

Trusted skf distributors ensure access to these innovative bearings worldwide.

- Universal Bearings Est.: Focuses on reliable availability of skf bearing products.

- Al-Wasat Al Badeel Trading Est.: Specializes in high-performance skf bearing solutions.

- Bearing World: Offers a comprehensive range of skf bearing and top-tier customer support.

Eco-Motion: SKF’s Cutting-Edge Bearings for a Greener Tomorrow

Low-Friction Technology

SKF’s low-friction bearings are key to energy-efficient machinery in 2025.

- Smooth Operation: Advanced designs reduce friction, boosting machine efficiency.

- SKF E2 Bearings: Achieve 30% lower frictional moment in motors.

- Heat Reduction: Less friction means cooler operation, saving energy.

- Wide Applications: Used in pumps, fans, and compressors.

Sustainable Lubrication Systems

SKF’s lubrication innovations enhance bearing performance while reducing environmental impact.

- Solid Oil Bearings: Eliminate relubrication, reducing grease waste.

- Eco-Friendly Grease: New polymer greases require less energy to produce.

- Longer Intervals: Extended relubrication periods cut maintenance needs.

- Wind Turbine Use: Specialized greases handle harsh conditions.

Remanufacturing for a Circular Economy

SKF’s remanufacturing services promote sustainability by reusing bearings.

- Energy Savings: Remanufacturing uses 10% of the energy of new bearings.

- Global Network: 15 remanufacturing centers worldwide reduce lead times.

- CO2 Reduction: Cuts emissions compared to new bearing production.

- Enhanced Features: Adds sensors or coatings during remanufacturing.

Smart Bearings with Sensors

SKF’s smart bearings integrate technology for better performance and sustainability.

- Condition Monitoring: Sensors track bearing health, preventing failures.

- Energy Optimization: Data helps optimize machine efficiency.

- Reduced Downtime: Early detection minimizes costly repairs.

- Industry 4.0: Supports smart manufacturing trends.

Trusted SKF Suppliers

Reliable skf suppliers ensure industries access these advanced bearings.

- Universal Bearings Est.: Provides consistent skf bearing availability.

- Al-Wasat Al Badeel Trading Est.: Offers specialized skf bearing expertise.

- Bearing World: Delivers a wide skf bearing range with proactive support.

Sustainability in Motion: SKF’s 2025 Vision for Eco-Friendly Bearings

Reducing Carbon Footprints

SKF bearings help industries lower their environmental impact significantly.

- CO2 Savings: SKF E2 bearings cut 2 tonnes of CO2 per motor yearly.

- Energy Efficiency: Bearings reduce power consumption across applications.

- Green Certifications: SKF aligns with global sustainability standards.

- Industry Impact: Supports eco-goals in automotive and renewable energy.

Magnetic Bearings for High Efficiency

SKF’s magnetic bearings offer a leap in sustainable performance.

- High-Speed Capability: Rotate up to 50,000 rpm with minimal friction.

- Lower Emissions: Used in compressors to cut CO2 output.

- Maintenance-Free: No contact reduces wear and upkeep.

- Clean Technology: Supports oil-free compressor systems.

Innovation Through R&D

SKF’s research drives the development of eco-friendly bearing solutions.

- Tribology Expertise: Over 100 years of friction and wear knowledge.

- New Materials: Exploring ceramics and polymers for efficiency.

- Digital Tools: SKF BEAST and BFree simulations optimize designs.

- Future Focus: Developing bearings for emerging green technologies.

Supporting Global Industries

SKF’s bearings cater to diverse sectors, enhancing sustainability.

- Aerospace: Lightweight bearings reduce fuel consumption.

- Railways: High-durability bearings support sustainable transport.

- Construction: Bearings handle heavy loads with less energy.

- Food Processing: Solid Oil bearings ensure clean operation.

Collaboration with SKF Bearing Suppliers

SKF bearing suppliers play a vital role in delivering these solutions.

- Universal Bearings Est.: Ensures steady skf bearing supply.

- Al-Wasat Al Badeel Trading Est.: Provides tailored skf bearing options.

- Bearing World: Offers extensive skf bearing inventory and expert guidance.

Why Choose Bearing World for SKF Bearings?

When selecting skf bearing suppliers, industries need reliability and expertise. Bearing World stands out with its comprehensive inventory, covering everything from SKF Explorer to E2 bearings. Their technical support team offers tailored recommendations, ensuring optimal performance for specific applications. With a focus on customer education, Bearing World provides resources to maximize bearing life and efficiency. Their proactive maintenance programs, including condition monitoring and remanufacturing guidance, help clients avoid downtime and reduce costs. Compared to others, Bearing World’s fast delivery and wide-ranging solutions make it a trusted partner for sustainable bearing needs in 2025.

Conclusion

SKF’s eco-friendly bearing solutions for 2025 are transforming industries. From low-friction SKF Explorer and E2 bearings to magnetic and smart bearings, the skf bearing company is leading the charge in sustainability. Their focus on energy efficiency, recyclable materials, and remanufacturing cuts costs and carbon footprints. Trusted skf distributors like Bearing World ensure these innovations reach industries worldwide. Proactive maintenance, supported by Bearing World’s expertise, maximizes bearing life and efficiency. For businesses aiming to embrace sustainability, partnering with reliable skf bearing suppliers is key. To explore a wide range of high-quality bearings and learn about proactive maintenance programs, visit www.bearingworld.com.sa/.