Regular inspection of your SKF timing belt is essential for both automotive and industrial applications. As a precision-engineered component, a timing belt synchronizes camshaft and crankshaft movement, directly impacting engine performance and longevity. Early detection of wear or malfunction can save thousands in emergency repairs. This blog covers 5 warning signs requiring immediate attention, explains SKF timing belt kit components, and offers cost-effective maintenance strategies for professionals and enthusiasts alike.

Understanding SKF Timing Belt Technology and Precision Engineering

SKF timing belts are manufactured using advanced materials and ISO-certified processes to ensure stability, wear resistance, and quiet operation.

- Engineered with aramid fibers for high tensile strength

- Rubber backing and tooth facing optimize friction and minimize slippage

- Automatic tensioner units maintain constant belt tension under varying temperatures

- Idler pulleys are crafted for precise belt guidance and reduced lateral movement

- Backed by SKF’s global quality assurance and testing standards

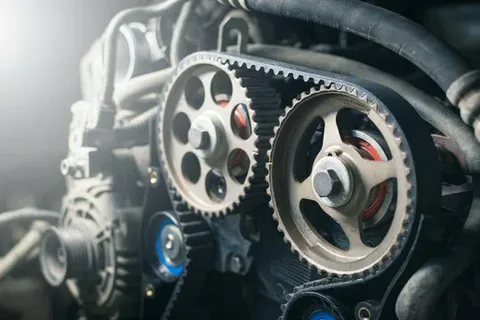

The Critical Role of Timing Belts in Engine Synchronization

Timing belts ensure valves open and close at exact moments, preventing piston-valve interference in interference-engine designs. Proper belt function:

- Maintains precise camshaft/crankshaft alignment

- Reduces engine vibration and noise

- Optimizes fuel efficiency and emissions control

- Protects against costly internal damage from mistimed valves

- Supports auxiliary components like water pumps and injection pumps

Five Warning Signs Requiring Immediate Maintenance Attention

1. Excessive Belt Noise

- Squealing or chirping during startup or idle

- Indicates misalignment or tensioner wear

- Continuous noise can lead to tooth degradation

- Correction: Realign pulleys, replace tensioner

- Preventive: Inspect noise sources bi-monthly

2. Visible Cracks or Fraying

- Inspect belt teeth and backing for splits or fiber exposure

- Cracks often appear near idler or tensioner contact points

- Left unaddressed, belt failure is imminent

- Solution: replace belt and inspect pulleys for wear

- Best practice: photograph belt condition for records

3. Oil or Coolant Contamination

- Fluid glazing softens rubber, reducing tooth engagement

- Appears as shiny, slick belt surfaces

- Immediate flush and replacement required

- Check for seals or hose leaks causing contamination

- Incorporate solvent cleaning in inspection protocol

4. Excessive Belt Stretch

- Measured by comparing belt marks after installation

- Stretch beyond manufacturer spec signals fatigue

- Tensioner may fail to maintain proper tension

- Replace belt and automatic tensioner as a kit

- Use torque-wrench for accurate tension adjustments

5. Tensioner or Idler Pulley Failure

- Listen for grinding or clicking from tensioner bearings

- Wobble indicates bearing deterioration

- Damaged tensioners lead to uneven belt wear

- Replace both belt and pulleys as part of a timing belt kit cost-effective solution

- Regularly lubricate bearing housings where applicable

Comprehensive Timing Belt Kit Components and Their Functions

An SKF timing belt kit includes all parts needed for a full system overhaul:

- Main timing belt with aramid tensile cords

- Automatic or manual tensioner unit

- Idler pulleys for optimal belt routing

- Water pump (in WP suffix kits) for cooling system integration

- Seals and gaskets for contamination prevention

Step-by-Step Installation Procedures with Proper Tools

- Secure engine at top dead center (TDC) using locking pins

- Remove old belt, tensioner, and idler pulleys

- Clean mounting surfaces and check sprocket condition

- Install new belt, aligning timing marks precisely

- Fit tensioner and rotate to apply correct preload

- Manually rotate engine two revolutions to verify timing

- Reinstall covers, adjust auxiliary belt tensions

- Conduct a test run and recheck tension

Maintenance Schedules and Inspection Protocols

- Inspect every 20,000 km or 12 months, whichever comes first

- Replace at 100,000 km or per OEM recommendation

- Check tensioner and idler pulleys at each oil change

- Perform leak inspection for oil/coolant contamination

- Keep detailed service logs with condition photos

Performance Benefits of SKF Timing Belt Kits Over Standard Alternatives

SKF’s precision engineering delivers:

- Extended service life under high load conditions

- Superior heat and oil resistance for harsh environments

- Quieter operation with reduced vibration

- Integrated water pump options for system efficiency

- Global availability and OEM compatibility

Integration with Water Pump Replacement for Complete System Overhaul

Co-replacing the water pump with the timing belt:

- Prevents repeat labor costs if pump fails later

- Ensures coolant system integrity

- Water pump in SKF WP kits meets OE performance specs

- Simplifies warranty claims and service records

- Improves long-term system reliability

Conclusion

Proactive inspection and timely replacement of your SKF timing belt and associated components not only protect critical engine synchronization but also significantly reduce long-term maintenance costs and downtime. Recognize the five warning signs—noise, cracking, contamination, stretching, and pulley failure—to ensure immediate action. For a complete, reliable solution and expert support, Visit Bearing World for genuine SKF timing belt kits, professional advice, and seamless service.